By definition, the Industrial Internet of Things or IIoT is referred to as the industrial framework that makes the usage of IoT devices in manufacturing and industrial processes more efficient. IIoT encompasses the use of IoT devices across industries such as Industry 4.0 or manufacturing, logistics, oil and gas, transportation, aviation, and other industrial sectors. Different IoT hardware devices such as sensors, industrial robots are used in these industries to gather real-time analytical data. IIoT has also flagged in the industrial sector era by automating processes, thus increasing reliability and efficient use of machinery in the field.

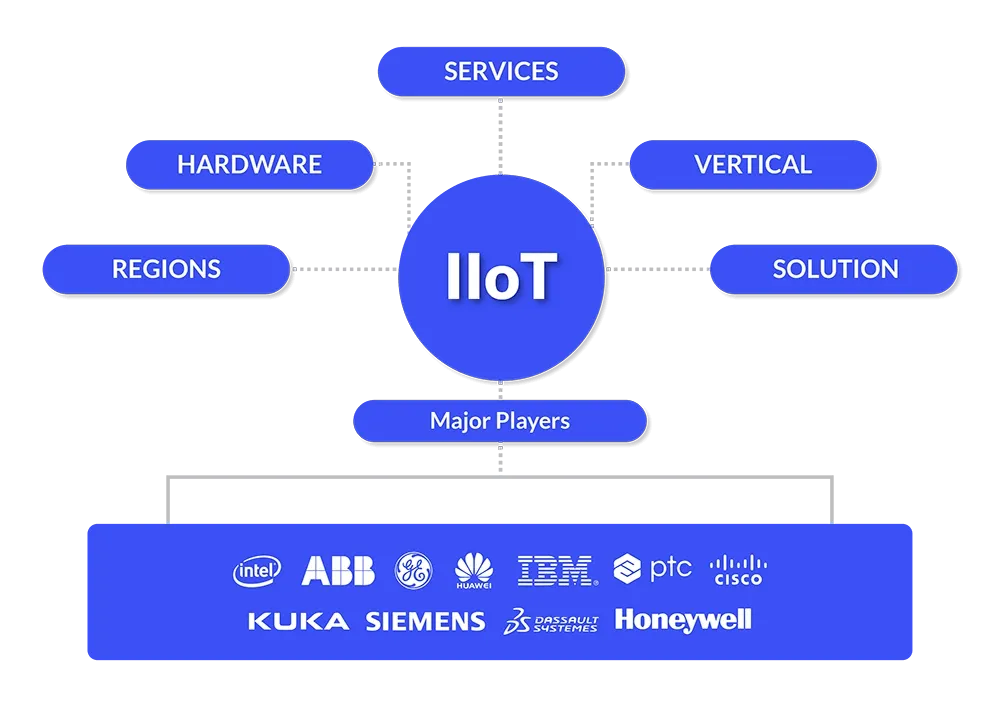

The global IIoT market is currently valued at USD 82.4 billion and is expected to grow with a CAGR of 21.3% between 2020-2028. The market of IIoT can be broadly classified into components, hardware, services, vertical, solution, and regions. A few key players in the market include Dassault Systèmes, Intel Corporation, Honeywell International, Cisco Systems Inc, ABB, ARM holding, Bosch.IO, Siemens AG, General Electric Company, Rockwell Automation, Texas Instruments Inc, Huawei Technologies, IBM Corporation, KUKA AG, NEC Corporation, and PTC Corporation. Many factors play a significant role in the growth of IIoT, including standardisation of IPV6, growing use of cloud computing platforms across industry verticals to support data management, a breakthrough advancement in the manufacturing industry, and most importantly, the arrival of Industry 4.0.

Relationship Between IoT and Efficiency in the Industrial Sector

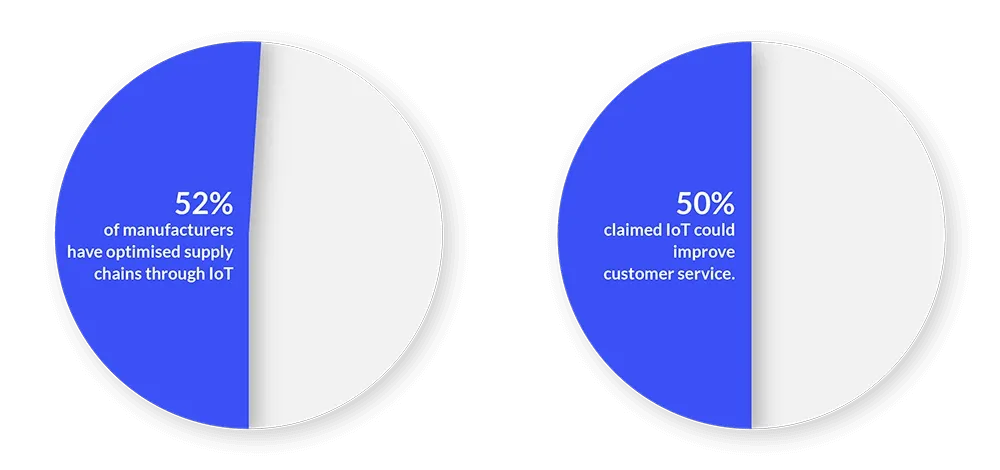

The most significant advantage of IIoT is the usage of reliable, real-time data to improve operational efficiency. IoT in manufacturing typically involves the use of RFID, barcoding, wireless networking, and real-time location data. A Forrester research reports that 52% of manufacturers have optimised supply chains through IoT, while 50% claimed IoT could improve customer service. IoT in manufacturing has proven to boost efficiency by supporting inventory management, asset maintenance, workforce management, and field service. As IoT provides better visibility into a business’s supply chain, manufacturers can monitor locations, product conditions in transit, and transit schedules.

Discover the transformative impact of IoT in manufacturing. Here's how IoT-based systems revolutionize efficiency:

IoT-Based Predictive Maintenance:

Leveraging IoT modules for real-time monitoring, these systems foresee potential issues in machinery, reducing downtime and enhancing equipment reliability.

Streamlining with IoT Automation:

IoT modules automate routine manufacturing tasks, minimizing time and human errors. This integration of IoT-based technologies smoothens workflow, simultaneously boosting speed and quality.

Energy Management through IoT Systems:

IoT-based solutions actively manage and optimize energy consumption in manufacturing, resulting in significant cost savings and an environmentally conscious approach.

Data-Driven Strategies via IoT:

Harnessing the extensive data generated by IoT modules, manufacturers can analyze and refine processes, leading to smarter, data-informed decisions that escalate productivity.

IoT Modules in Supply Chain Management:

IoT technology provides precise monitoring of materials and products in the supply chain. Enhanced inventory management, waste reduction, and an agile supply chain are the results of this IoT-based approach.

A report from the American Society for Quality (ASQ) revealed that manufacturers capitalising on IoT had witnessed an 82% increase in efficiency, 49% fewer product defects, and 45% increase in customer satisfaction. From inventory control, supply chain management, IoT has liberated industry production by connecting machinery and warehouse systems. Thanks to the amount of data collected from different manufacturing devices, industries have reduced overhead costs, conserve resources, increase profit margins, and optimise operational efficiencies. IIoT has several proven benefits. Some of them are listed below.

| Predictive machine maintenance allows better asset usability. |

| Personnel allocation based on data gathered enhances workforce management. |

| Optimal utilization of warehouse leads to effective plant organization. |

| Control over temperature, ventilation, lights can improve energy usage. |

| Informed decisions on downtime, order status, and routes lead to better logistics optimization. |

Impact of IoT on Industries

Elevating Aviation Efficiency with IoT

In the aviation sector, IoT is a game-changer for managing complex global logistics. Key applications include advanced baggage handling with connected trackers and proximity sensors, significantly reducing baggage mismanagement.

IoT Advancements in Retail

The retail industry harnesses IoT for critical aspects like supply chain management and food safety. IoT sensors offer comprehensive tracking, providing vital data on environmental conditions, thereby ensuring product quality and traceability. In food retail, IoT aids in monitoring storage conditions, playing a pivotal role in reducing perishable food spoilage and ensuring freshness.

Transformative IoT Applications in Healthcare

IoT technologies are increasingly vital in healthcare, especially for remote patient monitoring. They track vital health parameters and enhance patient care with smart hospital beds. During health crises like the COVID-19 pandemic, IoT devices such as connected thermometers and heart monitors have been instrumental in monitoring high-risk patients remotely, reducing infection risks.

IoT in Building and Energy Management

In building management, IoT leads the way in optimizing energy usage and maintenance. Smart thermostats and lighting systems auto-adjust based on occupancy and natural light, significantly cutting energy consumption. IoT also enables proactive building maintenance, using sensors to track structural integrity and anticipate maintenance needs, thus averting costly repairs.

Optimizing Energy and Maintenance with IoT in Buildings

IoT is pivotal in managing energy consumption and building maintenance. By monitoring energy use patterns, IoT helps businesses manage their energy more effectively, avoiding peak rates. Continuous structural monitoring through IoT sensors facilitates timely maintenance and safeguards building integrity.

Industry 4.0 welcomed the industrial revolution by leveraging the Internet of Things’ benefits to implement smart manufacturing units. For instance, to create fully automated smart factories using the internet, Siemens created Mindsphere - a cloud-based IoT system. The system efficiently collects data from all machines and devices in the factory and uses analytics to study the data to arrive at a solution to optimise production. Hitachi, a leading Japanese conglomerate, developed an IoT-based production model to eliminate production lead time by half. By adopting IoT on their manufacturing floor, companies have seen significant results such as

- Lowered energy costs

- Coordinated operations

- Improved supply chain

- Better office efficiency

IoT Applications in Industrial Automation

The integration of the Internet of Things (IoT) in industrial automation signifies a transformative shift in manufacturing and production processes. Let's explore the primary applications where IoT makes a significant impact:

Predictive Maintenance:

Utilizing IoT sensors attached to machinery, industries can predict potential breakdowns before they occur, significantly reducing downtime and maintenance costs. This predictive approach ensures continuous operational efficiency and enhances machinery longevity.

Real-Time Monitoring:

IoT devices enable the live monitoring of critical parameters such as temperature, pressure, and humidity, boosting process control and operational efficiency. This real-time data stream helps in making informed decisions that enhance productivity and efficiency.

Enhanced Operational Efficiency:

Through the automation of routine tasks, IoT contributes to increased production throughput while minimizing human errors. The seamless integration of IoT devices fosters an environment of heightened operational efficiency, directly influencing productivity metrics.

Energy Management:

IoT sensors play a crucial role in energy conservation by identifying areas of energy wastage and optimizing usage. Effective energy management not only promotes sustainability but also reduces operational costs in industrial settings.

Supply Chain Optimization:

IoT dramatically improves supply chain management by providing enhanced tracking capabilities for materials and products. This optimization leads to better inventory management and streamlined logistics, enhancing the overall supply chain efficiency.

Worker Safety:

By employing IoT wearables, industries can monitor worker health and safety in real-time, ensuring a safer workplace environment. These devices can alert to hazardous conditions, improving safety protocols and worker protection.

Quality Control:

IoT facilitates continuous monitoring of production lines, ensuring that manufacturing standards are met and maintained. This constant vigilance helps in upholding high-quality standards across production outputs.

Smart Factory Integration:

IoT is integral to developing interconnected, efficient smart factory systems. These smart factories leverage IoT for better data integration, operational visibility, and automated control systems, paving the way for innovative manufacturing strategies.

Customization and Flexibility:

IoT technology enables the rapid reconfiguration of production lines to adapt to changing consumer demands and market conditions, offering unparalleled customization and flexibility in manufacturing processes.

IIoT innovations by significant players in the industry

From aviation to agriculture, IIoT has provenly revolutionised various segments within an operational process. Leading industry players have used industrial IoT applications to drive their business. Here are some examples.

Factory of the Future by Airbus

To tackle the complex assembly of commercial jetliners efficiently, Airbus launched Factory of the Future that streamlined operations and improved production capacity. By integrating sensors to tools and shop floor machines and using wearable technology such as smart glasses, Airbus reduced errors and improved workplace safety.

Track and Trace program by Bosch

Launched in 2015, the idea was to minimise workers' time to hunt down tools by adding sensors to the tools. The system was later adopted to guide assembly operations.

Zero Downtime (ZDT) system by Fanuc

ZDT system was created for predictive maintenance of their assets by using sensors within robotics to work in tandem with cloud-based analytics. Fanuc's system has allowed the company to predict the failure of components much efficiently and quickly.

Industrial IoT is about taking advantage of the advancements in technology. Over the last decade, IIoT has improved resource utilisation, assisted in efficient production, and revamped management models. While a future without an assembly line seemed near impossible, innovations such as the Internet of Things have geared up industries through remarkable growth. As more data is available now, the IIoT revolution is only just beginning. With different sectors such as retail, healthcare, smart home, energy and utility, automotive and logistics, and smart city adopting IIoT, it is predicted to make an impact on global GDP at USD 14 trillion by 2030.

The future of IoT in manufacturing

The future of IoT in manufacturing is poised for significant advancements, driven by the widespread adoption of IoT across various industries. Smart factories will emerge, combining IoT with AI and robotics to optimize processes and reduce human intervention. IoT will enhance supply chain transparency through real-time tracking, improve workplace safety with proactive monitoring, and enable customized production to meet consumer demands. Supporting technologies like edge and fog computing will reduce latency and improve data processing efficiency. With the number of connected devices expected to reach 75.44 billion by 2025, IoT will continue to revolutionize manufacturing, leading to greater efficiency, better resource management, and a more adaptable production environment.

Role of an IoT gateway in increasing Industrial Efficiency

In an effort to increase industrial efficiency it is paramount to decrease the latency between devices and the platform and to achieve this, each part of the process including the software needs to be optimized and aggregated.

An IoT gateway is a device that aggregates data from different devices and performs critical functions such as device connectivity, translating protocols, managing and filtering data, and much more; bridging the communication gap between different IoT devices such as sensors, equipment, systems and the cloud, where the data is finally processed. Simply put, the gateway functions within an IoT ecosystem as an intermediary between devices and sensors that help communicate with the cloud. IoT gateway is necessary for scalability, mitigating risks, improving time-to-market, cost benefits, lower latency, and security.

In Industrial IoT, the gateway connects machineries, sensors, actuators, remote PCL controllers, and many other automation-enabled devices. For IoT users in the industrial and manufacturing segment, the IIoT gateway offers greater processing power and security than a gateway of any other IoT segment such as a smart home due to the added security features and encryption. A cellular gateway provides all this functionality while providing access to the cloud with a cellular network.

How does a player from industries such as automotive, manufacturing, logistics, energy identify the right components of IoT gateway within their IoT ecosystem?

Cavli’s LTE Cat 1 & 4 Smart Modules - The answer to efficient Cellular IIoT Gateways

Are you looking for efficient cellular IIoT gateways? Cavli’s LTE Cat 1 IoT module and LTE Cat 4 IoT module are your ideal solutions. These modules provide reliable, secure, and high throughput data connectivity with low power consumption. Whether you need medium data throughputs with LTE Cat 1 or higher speeds with LTE Cat 4, Cavli has you covered. The integrated eSIM ensures uninterrupted connectivity, while support for robust protocols like MQTTS, CoAP, and HTTPS ensures seamless communication. Choose Cavli’s Smart Modules for your IoT applications and experience unparalleled efficiency and performance.

Features:

- Integrated eSIM and global connectivity through Cavli Hubble

- Intelligent/Automatic local eSIM provisioning

- Advanced firmware installation/update over-the-air

- PAYG global data subscription mode

- High carrier-class network security

- Optimised for higher bandwidth, including voice