In the age of digital transformation, sensors in Internet of Things (IoT) stand at the forefront, driving innovation across diverse industries. From smart cities to healthcare, these tiny, powerful devices are revolutionizing how we interact with the world around us.

For example, visualize a meeting room with optimized temperature. Have you ever wondered how this seamless comfort is achieved?

The answer lies in the sophisticated world of IoT sensors. From temperature and occupancy sensors to light and motion sensors, the different types of IoT sensors ensure an optimal environment for every occupant.

In the world of IoT, the most critical element is data. This data, which drives the intelligence and functionality of IoT devices, is primarily gathered by IoT sensors. These small yet powerful components are the backbone of any IoT system.

In this blog, we will explore the different types of sensors in IoT and unlock their intricacies, highlighting how they are indispensable to the IoT ecosystem.

What is a Sensor? Understanding the Key to Smart IoT Technology

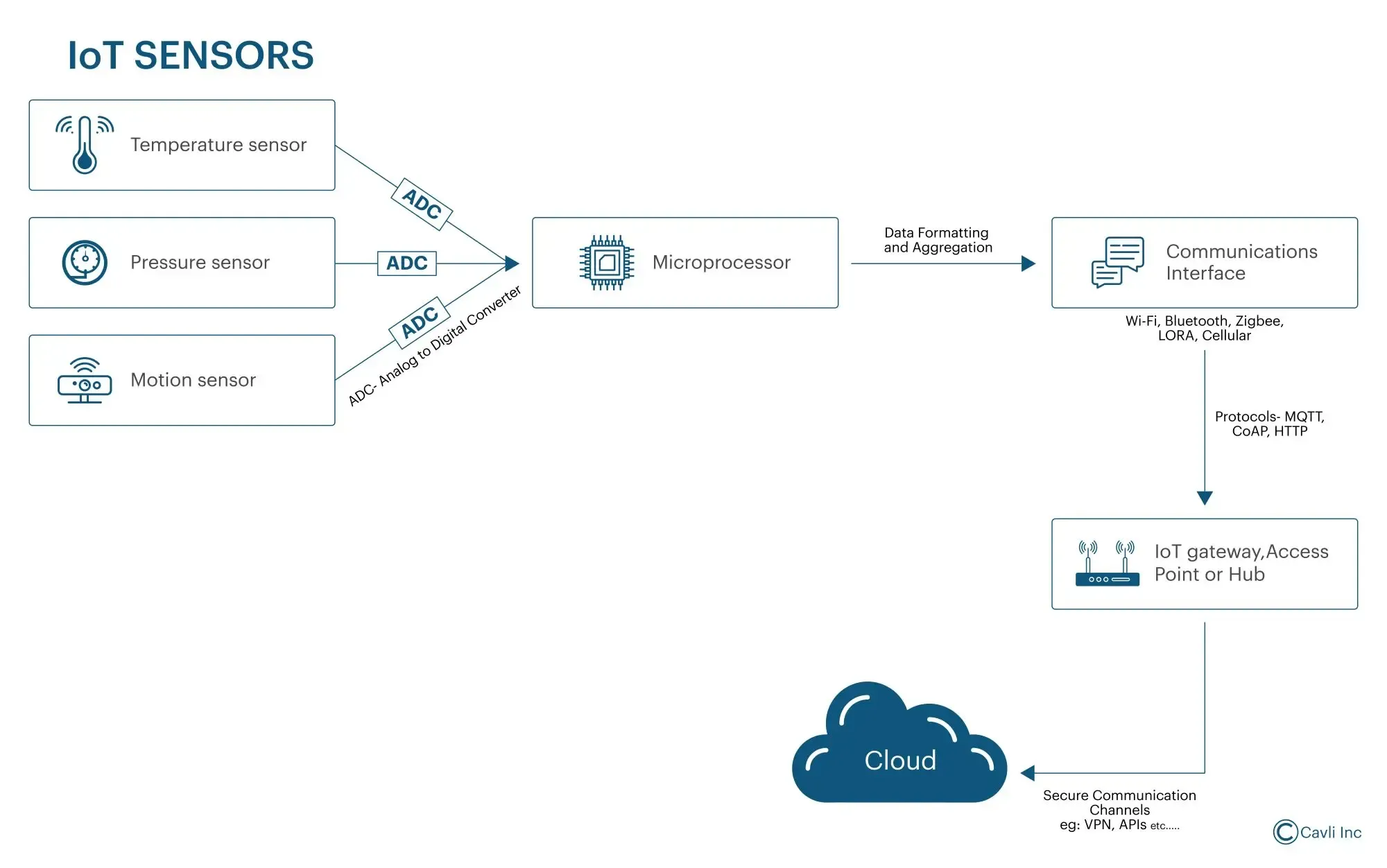

A sensor is a device that detects and responds to various inputs from the physical environment, such as light, heat, motion, moisture, or pressure, and converts these into digital signals that IoT devices can interpret and act upon.

The output from a sensor is generally a signal, often in the form of electrical voltages or digital data, which can be processed and converted into meaningful information or actionable insights.

This conversion typically occurs at the sensor location or within a connected processing unit. The information can then be displayed as text, graphs, or other formats, or used to trigger automated responses in IoT systems.

Working of an IoT sensor

Functions of an IoT Sensor

As we have discussed sensors in office spaces, let's now take a tour of a chemical processing plant.

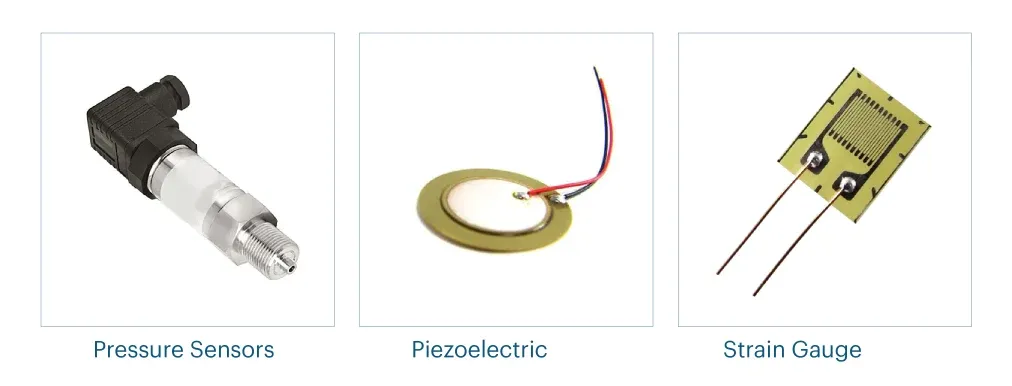

Emergency! The plant’s control room is on high alert. The pressure sensors have detected a pressure spike beyond the safe threshold, and the gas sensors indicate a slight increase in hazardous gas levels.

We just averted a major hazard, thanks to the timely intervention of sensor technology. From data collection to data-driven decisions, sensors in IoT systems have three fundamental functions:

Monitoring

Sensors continuously monitor parameters and ensure that systems operate within their desired thresholds. This involves using sensors to keep a constant watch on various environmental and operational factors. By continuously collecting and analyzing data, sensors enable the early identification of potential issues, ensuring that systems operate efficiently and safely without downtime.

Data Collection

Sensors collect real-time data constantly from their physical surroundings. If any anomaly is found in the network, they pass information to the central system for informed decision-making thus eliminating potential downtime. IoT applications also support data transmission to cloud platforms for real-time data processing and advanced analytics.

Automation

Sensors also play a part part in automating systems to perform specific actions. This eliminates the need for human intervention and enables devices to respond to changing conditions in real time.

Classification of Sensors

| Sensing Parameter | Sensors |

|---|---|

| Measured Property | Physical and Chemical sensors |

| Output Signal | Analog and Digital sensors |

| Contact Type | Contact and Non-Contact sensors |

| Application | Environmental sensors, Industrial sensors, Medical sensors, Automotive sensors, Agricultural sensors |

| Operating Principle | Capacitive sensors, Inductive sensors, Optical sensors, Piezoelectric sensors, Magnetic sensors, Thermal sensors |

1. Physical and Chemical Sensors

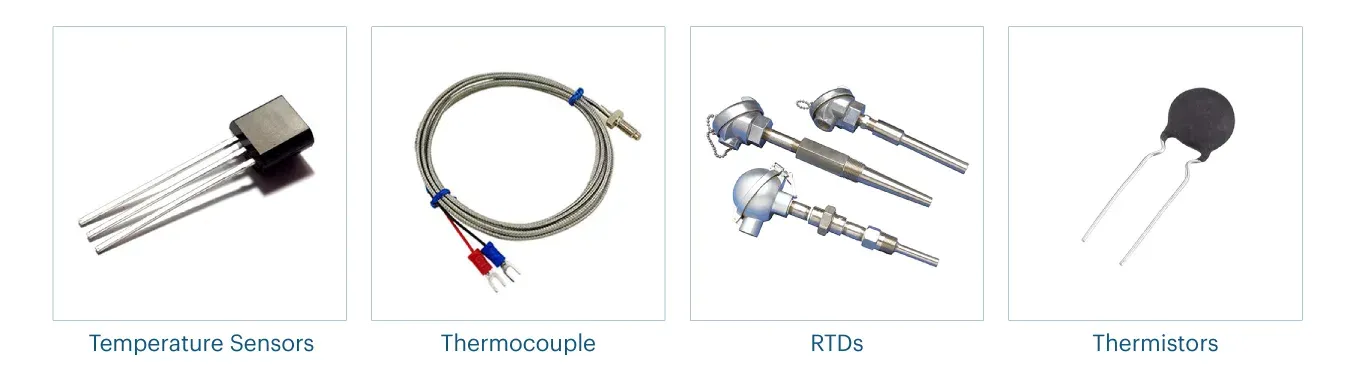

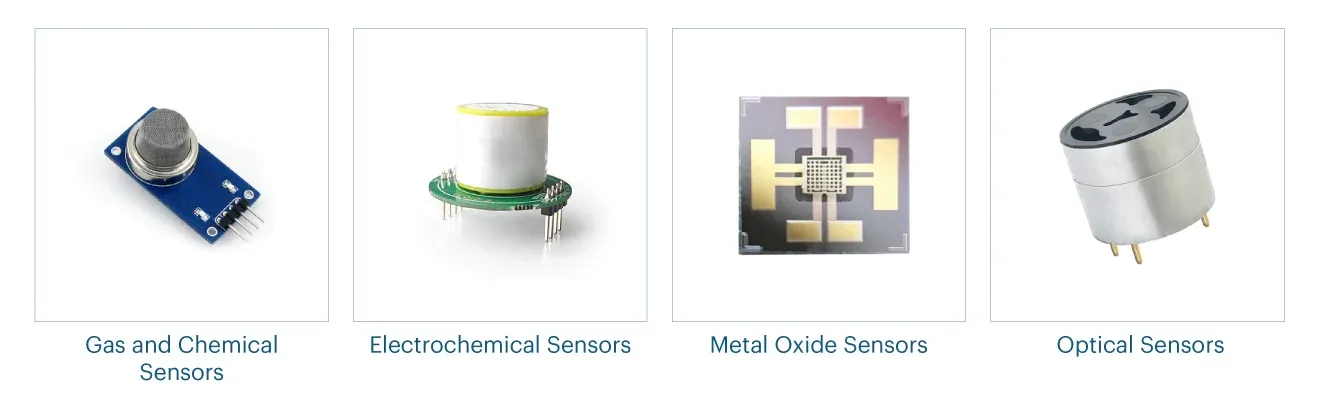

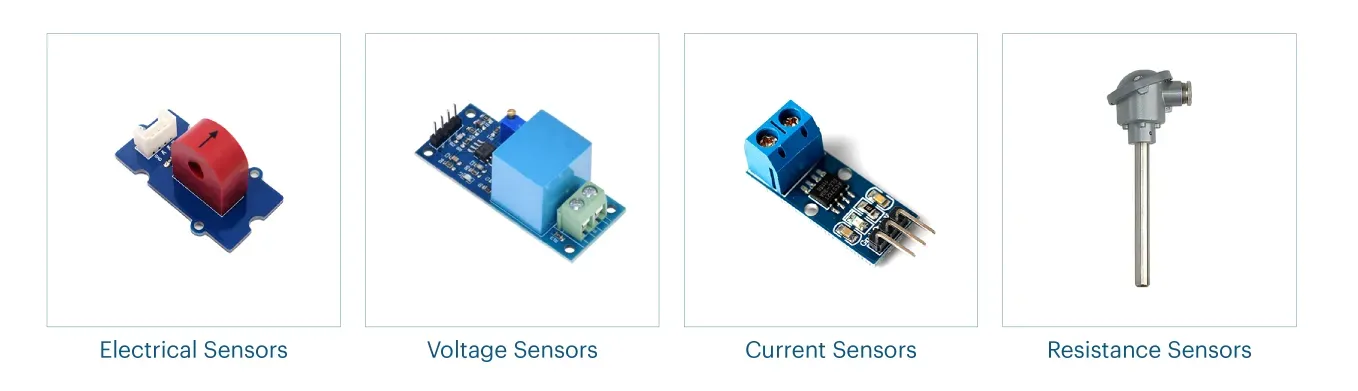

There are two types of sensors based on the properties sensors intend to measure:physical and chemical sensors. Physical sensors measure aspects such as temperature, pressure, and motion, and chemical sensors detect properties like gas concentrations and pH levels.

2. Analog and Digital Sensors

Sensors are classified according to the type of signals they produce: analog and digital sensors. Analog sensors provide continuous signals that vary proportionally with the measured quantity, while digital sensors output discrete signals, typically in binary form.

3. Contact and Non-Contact Sensors

This classification is based on whether the sensor requires physical contact with the object or environment it is measuring. Contact sensors need to touch the measured entity, whereas non-contact sensors can measure from a distance.

4. Application-based Sensors

This classification groups sensors according to the specific industry or use case they are designed for. It includes sensors tailored for industrial automation, automotive systems, medical diagnostics, and environmental monitoring, each with specialized requirements and characteristics.

5. Operating principle-based Sensors

Some sensors work on specific technologies or methods that detect and measure parameter changes. Sensors operating on principles such as changes in resistance, capacitance, inductance, or piezoelectricity sensors are examples of these sensors.

Factors to Consider when Selecting Sensors for your IoT Applications

There are several factors to consider when building IoT sensor applications. These attributes will determine how well the sensor performs in your specific environment and how effectively it integrates with the rest of your system. Balancing these factors against your project's requirements and constraints will help you choose the most appropriate sensor for your needs.

1. Measurement Requirements

To accurately measure a specific physical quantity or parameter, such as temperature, humidity, pressure, motion, or light, it is essential to identify the particular measurement needs of your application. Consider the required accuracy, i.e., how close the measurement must be to the true value, and sensitivity, referring to the smallest change the sensor can detect.

For example, for selecting a temperature sensor for smart home solutions, we typically choose the sensor that operates within the temperature range typical for residential settings, i.e., -20°C to 50°C. In the modern smart home applications, the DS18B20 temperature sensor is selected as it ensures precise temperature readings and adequate sensitivity to detect small changes.

2. Environmental Conditions

Consider operating under environmental conditions, such as extreme temperatures or high humidity. If the sensor will be used in harsh environments like industrial settings or outdoors, opt for one that is durable and rugged, with features like waterproofing, dustproofing, or chemical resistance. Additionally, SNR, a measure of the strength of the signal relative to the background noise and electromagnetic interference (EMI) also influences the selection of sensors.

The barometric pressure sensors, like BMP280 and BME680 sensors, are popular choices for measuring atmospheric pressure in weather monitoring applications due to their accuracy, compact size, and additional functionalities. With its ability to detect gasses and provide air quality index readings, the BME680 is helpful for applications that require a broader environmental analysis, such as indoor air quality monitoring.

3. Power Requirements

Choosing sensors that offer low-power operation modes or can be powered down when not in use is essential for battery-powered IoT devices. This minimizes power consumption and extends battery life. Additionally, it is necessary to ensure that the sensor's power requirements are compatible with the available power supply.

The capacitive soil moisture sensor (SEN0193) measures the volumetric water content in the soil by detecting changes in capacitance. Being deployed in vast agricultural fields powered by battery-operated and solar-powered IoT systems, the SEN0193 efficiently operates with minimal power, making it ideal for low energy requirements. It can be easily integrated with microcontrollers that have power-saving modes, allowing the IoT system to conserve energy by putting the sensor into a low-power state when not actively measuring.

4. Communication and Interfaces

Communication protocols and interfaces such as I2C, SPI, UART, Modbus, Bluetooth, or Zigbee pa major role in data transmission using digital sensors. For real-time applications that require fast data transmission, it is important to make sure the sensor can handle the necessary baud rate and bandwidth. Baud rate refers to the speed at which data is transmitted over a communication channel. Additionally, it is necessary to determine whether a wired or wireless connection is more suitable, depending on the deployment environment and the need for mobility.

Sensors like the ADXL345 (accelerometer) are used for motion detection in portable devices, robotics, gaming controllers, or in vibration monitoring in machinery and typically require fast, high-frequency data transfers. In such situations, the role of communication protocols and baud rate is important in maintaining efficient communication.

5. Response Time and Sensitivity

In time-sensitive applications, such as motion detection, the sensor's response time is crucial, as it determines how quickly the sensor can detect changes and report data. Additionally, ensure that the sensor's sensitivity is adequate to detect the necessary level of change in the measured parameter, especially in scenarios where small variations are important.

For example, in security systems, smart lighting, and automatic doors, the PIR (Passive Infrared Sensor) Motion Sensor has a fast response time, allowing it to quickly detect motion and trigger actions like turning on lights or sounding alarms.

6. Impedance Matching and Signal Integrity

When working with analog sensors, it's important to ensure that the sensor’s output impedance matches the input impedance of the next stage in the circuit to avoid signal loss or distortion. For high-frequency or high-precision applications, considering factors that could impact signal integrity, such as impedance matching, signal-to-noise ratio (SNR), and others, is important. These considerations are key to maintaining accurate and reliable sensor performance.

Electrocardiogram (ECG) sensors like the ADS1298 ECG sensor, used for monitoring heart activity, should have output impedance of the ECG electrodes matching the input impedance of the amplifier circuit. Mismatched impedance can lead to signal loss, distortion, or increased noise, compromising the accuracy of the heart rate readings.

Major Players in Sensor Manufacturing

| Manufacturer | Country | Headquarters | Founded | Market Cap | Sensors Manufactured |

|---|---|---|---|---|---|

| Texas Instruments | United States | Dallas, Texas | 1930 | Approx. $195 billion USD | Temperature sensors, Hall effect sensors, Proximity sensors, Light sensors, Motion sensors |

| Honeywell International | United States | Charlotte, N. Carolina | 1906 | Approx. $135 billion USD | Pressure sensors, Temperature sensors, Humidity sensors, Gas sensors, Motion sensors, Industrial sensors |

| Bosch Sensortec | Germany | Reutlingen | 1886 | Approx. 950 billion INR | MEMS sensors, Pressure sensors, Temperature sensors, Gas sensors, Accelerometers, Gyroscopes, Environmental sensors |

| TE Connectivity LTD | Switzerland | Schaffhausen | 2007 | Approx. $45 billion USD | Pressure sensors, Temperature sensors, Humidity sensors, Force sensors, Position sensors |

| NXP Semiconductors N.V | Netherlands | Eindhoven | 1953 | Approx. $65 billion USD | Accelerometers, Gyroscopes, Magnetometers, Pressure sensors, Temperature sensors |

| Analog Devices Inc | United States | Wilmington, Massachusetts | 1965 | Approx. $110 billion USD | MEMS sensors, Temperature sensors, Pressure sensors, Accelerometers, Gyroscopes |

| Rockwell Automation | United States | Milwaukee, Wisconsin | 1903 | Approx. $30 billion USD | Proximity sensors, Photoelectric sensors, Temperature sensors, Pressure sensors, Industrial sensors |

| Amphenol Corporation | United States | Wallingford, Connecticut | 1932 | Approx. $80 billion USD | Pressure sensors, Temperature sensors, Position sensors, Gas sensors, Humidity sensors |

| Siemens | Germany | Munich | 1847 | Approx. 130 billion euros | Industrial sensors, Proximity sensors, Pressure sensors, Flow sensors, Temperature sensors, Environmental sensors |

| Bharat Electronics Limited (BEL) | India | Bengaluru, Karnataka | 1954 | Approx. 2 trillion INR | Radar sensors, Environmental sensors, Proximity sensors, Motion sensors |

| Vishay Components India Private Limited | India | Pune, India | 1962 | Approx. $3 billion USD | Optical sensor, Force sensor, Position sensor, Proximity sensor, Temperature sensor |

| Toshniwal Instruments Pvt. Ltd. | India | Chennai | 1959 | Approx. $1 billion USD | Pressure sensors, Temperature sensors, Flow sensors, Humidity sensors |

Note: The companies are arranged in no specific order.

Types Of Sensors

Closing Notes:

Sensors are fundamental to the growth and effectiveness of IoT systems. Each sensor in a connected ecosystem plays a crucial role in enabling IoT systems and collecting the data to act upon.

This blog is an introduction to sensor technology, dealing with the functions, types, and classification of sensors. In the next part of this sensor tech series, we are going to dive into different sensors, and their applications, and more about them.